![PACE_edited-1]()

These days there are a number of crate engines that can provide you with a dependable driver. Aftermarket companies are producing a multitude of parts, various components and even full-on race engines in crate form. If you’re looking to go fast, have a shiny engine for your show car or just a dependable mill for your daily driver, and do it on a ramen budget, a crate engine may be exactly what you are after.

![Pace Performance is a complete one-stop-shop for everything Chevy. From pink engine dress-up kits to hardcore racing crate engines.]()

Pace Performance is a complete one-stop-shop for everything Chevy. From pink engine dress-up kits to hardcore racing crate engines.

Why Buy a Crate Engine?

Generally speaking, defining a crate engine is simple and for our purposes, “crate engine” refers to an engine that’s shipped complete, at least up to the cylinder heads. There’s really no drawbacks to a crate engine. Largely they are very affordable, built by engine builders that know what they are doing, have a warranty that backs the quality of the product, and all you have to do is drop the engine in and go.

Building your own engine may inflate your value of self-importance, but there’s really no beating a combination that has already been developed and tested like a turn-key crate engine.

Crate engines are not a new idea. For years GM Performance, now Chevrolet Performance, have been producing affordable crate engines for cheeseburger budgets. More recently, Pace Performance has gotten into the game of supplying the aftermarket with fully assembled crate engines to fit into any budget. This buyer’s guide will deal strictly with crate engines designed specifically for the Hot Rod, Street Rod or mild Street/Strip Rod.

Crate engines from Pace Performance are built by professional engine builders with aftermarket parts from companies that are known for quality and consistency. Most of Pace’s crate motors come with a great warranty to back up your purchase, which adds an extra level of comfort in the purchase.

How to Select a Crate Engine?

“The first consideration when selecting a crate engine has to be the application,” says Chuck Fitch. “If you have a daily driver, you probably are looking for a crate with EFI for fuel economy, power and superb dependability.” Companies like Holley and MSD are making quality EFI systems that are easily added to the Intake system of a SBC or LS engine.

![pacelogo]() Price is always a consideration for buying an engine or having one built. Crate engines gained popularity by providing decent power at a budget price point and this has continued to be the norm. If you want a base small-block Chevy, a crate engine will cost you less than building the engine yourself with the same caliber components, and don’t forget, the crate engine will be backed by a warranty. Fitch told us, “Before a customer spends his hard earned money on a crate engine, we want it to be the right one for his ride.”

Price is always a consideration for buying an engine or having one built. Crate engines gained popularity by providing decent power at a budget price point and this has continued to be the norm. If you want a base small-block Chevy, a crate engine will cost you less than building the engine yourself with the same caliber components, and don’t forget, the crate engine will be backed by a warranty. Fitch told us, “Before a customer spends his hard earned money on a crate engine, we want it to be the right one for his ride.”

Durability is an important factor for most crate engine buyers. “Unless they are people that like to work on engines, a customer is going to want an engine that is going to live for a long time,” says Fitch. “Many crate engine customers want an engine that runs reliably on pump gasoline. Our 10:1 and lower compression engines will keep the fuel cost down because you don’t have to buy expensive racing gas.”

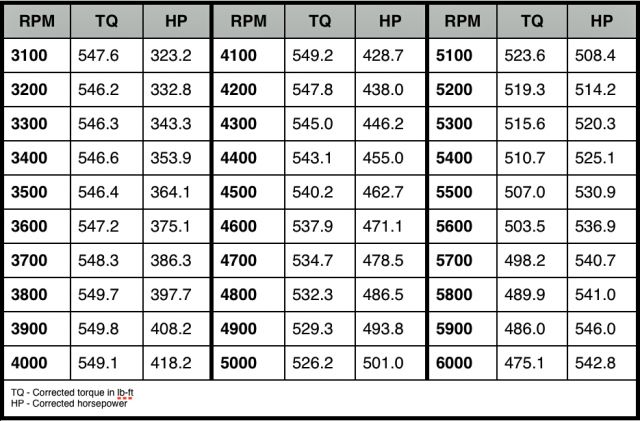

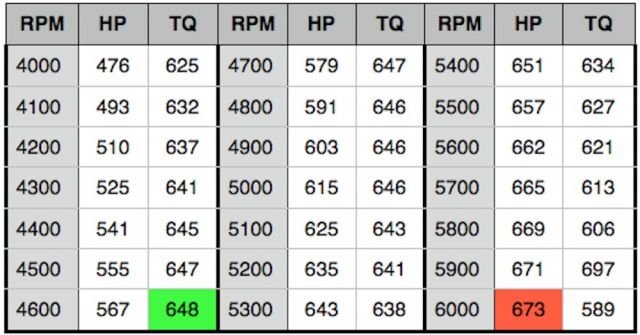

There are a lot of specs and stats that get published on every engine built. Most consumers are looking at the peak horsepower number but not the torque number. Many of the crate engines have a similar horsepower range but some of them have substantially more torque. At the low end, Torque is what gets the vehicle moving. If you want the car to move faster at lower rpm, shop for an engine that has a higher peak torque in the lower rpms.

How Does Pace Performance Build Their Crate Engines?

![Pace Performance also has the tech department to help you get the exact part you need. From measuring an LS engine crank pulley to finding the right crate engine for your application.]()

Pace Performance also has the tech department to help you get the exact part you need. From measuring an LS engine crank pulley to finding the right crate engine for your application.

“We start with a great base to work with, primarily with a Chevrolet Performance crate engine,” explains Fitch. Using the Chevrolet crate engine as a base makes a lot of sense. As Fitch explained to us, “The factory built crate engines go through durability testing on the parts and assembly. Most aftermarket companies are not subject to this same level of scrutiny. We can take this dependable foundation and build upon it,” he said. “We can tailor the crate engine even further by using quality parts from Holley, MSD, PROFORM, Edelbrock, FAST and a few others. This helps us offer a custom engine right off-the-shelf.”

Buyer’s Guide

The crate engines that you will see here include small-bock Chevy engines and LS engines which come complete from carburetor or EFI to the oil pan. Categorizing crate engines is a difficult chore because one engine may cross categories and be applicable in different applications. We’ve broken it down to four basic categories: Gen I SBC Carbureted, Gen I SBC EFI, LS with Carburetor and LS with EFI. With some guidance, we put these crate engines in the category that fit them best, with a budget, midrange, and king-of-the-road models. For fun, we have also picked a couple of unique and special crate engines from pace that caught our eye.

SBC Complete Carbureted Crate Engine

For Hot Rods, Street Rods and daily drivers, nothing beats the tried and true Gen I small-block Chevy engine. This engine has been a staple for project car builders since its inception. The small size and decent power range has endeared it to the automotive community having powered every type of vehicle imaginable.

For ease of comparison, we are listing the crate engines with their specs as published by Pace Performance.

Budget level SBC Carbureted Crate Engine

![]()

The basic stock 350 crate engine with carb (Part #GMP10067353-1) is difficult to beat for performance at this price.

Chevy 350 Complete, Fully Assembled Engine Package (Part #GMP-10067353-1) is the basic no frills engine package that makes it a perfect buy for those on a tight budget or for an ordinary daily driver. This turn-key GM 350 cid engine comes fully assembled using a brand new GM 10067353 350 cid 4-bolt main long-block which Pace has preinstalled all name brand components needed to make this engine ready to run, right out of the crate. A clutch Z-Bar hole is drilled and tapped for manual trans applications, and the block has engine mount holes drilled and tapped for both early-style front motor mount brackets and the normal side motor mounts.

Listed Price: $2,689.88

Application: Economical, daily driver

Cost per hp: $10.35

Specifications:

- Power: 260 hp at 4,300 rpm, 350 lbs/ft of torque at 3,600 rpm

- Displacement: 350 cid, 5.7L

- Bore x Stroke: 4.00-inch x 3.48-inch

- Compression Ratio: 8.5:1

- Block: Cast Iron, 2 piece rear seal, 4-bolt main caps

- Camshaft: Hydraulic Flat Tappet

- Cam Lift: .383-inch Intake / .401-inch Exhaust

- Cam Duration at .050-inch: 194 degree Intake / 202 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: Cast Iron, 3/8-inch pressed in rocker studs

- Maximum GM Recommended rpm: 5,100

![]()

An entry level performance crate engine with a little flash (part #GMP-12496968-1) includes chrome air cleaner and valve covers.

Mid-range SBC Carbureted Crate Engine

Everything you need in one very economical engine package. These turn-key engines come completely assembled and include stamped steel chrome valve covers and chrome air cleaner. All you need to do is transfer over your belt driven accessories and you’re ready to run. The ZZ4 is currently Pace Performance’s most popular crate engine.

With a long history of successes in drag racing as well as street rods and other performance applications, the ZZ4 might just be the bullet for your next project. The ZZ4 crate engine is available in a chrome finish (part #GMP-24502609-1) , a black finish (Part #GMP-24502609-2) or the crate with polished finish (Part # GMP-24502609-3).

The ZZ4 is currently Pace Performance's most popular crate engine. Available in chrome finish, black finish or polished finish.

Listed Price: $5,028.88 (chrome), $5,078.88 (black), $5,158.88 (polished)

Application: Daily driver, Street Rod, Street/Strip

Cost per hp: $14.16 (chrome), $14.30 (black), $14.53 (polished)

Specifications:

- Power: 355 hp at 5,400 rpm, 405 lbs/ft of torque at 3,600 rpm

- Displacement: 350 cid, 5.7L

- Bore x Stroke: 4.00-inch x 3.48-inch

- Compression Ratio: 10:1

- Block: cast iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: steel hydraulic roller tappet

- Cam Lift: .474-inch Intake / .510-inch Exhaust

- Cam Duration at .050-inches: 208 degree Intake / 221 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: Aluminum, 3/8-inch screw-in rocker studs

- Maximum GM Recommended rpm: 5,800

![]()

This 383 cid engine kit (part #GMP-2096-1) is a great value if you are willing and able to do some of the assembly yourself.

The ZZ4 crate engines may be the most popular but we found another Pace performance crate that offers a lot of horsepower at a reasonable price. The 383 cid engine kit (Part #GMP-2096-1) provides an engine with plenty of low-end torque and all you have to do is assemble and provide a carburetor, air cleaner and distributor. A couple of hours in assembly and you have a very affordable and dependable 383 cid performance engine.

Listed Price: $6,379.95

Application: Daily Driver, Street Rod, Street/Strip

Cost per hp: $13.87

Specifications:

- Power: 425 hp at 5,400 rpm, 449 lbs/ft of torque at 4,500 rpm

- Displacement: 383 cid

- Bore x Stroke: 4.00-inch x 3.80-inch

- Compression Ratio: 9.5:1

- Block: cast iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: steel hydraulic roller tappet

- Cam Lift: .594-inch Intake / .594-inch Exhaust

- Cam Duration at .050-inch: 242 degree Intake / 240 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: Edelbrock rpm E-TEC 200, 3/8-inch screw-in rocker studs.

- Maximum GM Recommended rpm: 6,000

Upper-range SBC Carbureted Crate Engine

Chevrolet Performance Parts fully assembled ZZ383 sporting 425 hp takes the award for top SBC naturally aspirated crate engine from Pace Performance. These fully dressed ZZ383′s offer Big Block performance with a Small Block price tag by offering an incredible 460 lbs/ft of torque at 4,500 rpm. The combination of a 3.800 steel crank and a stout .509/.528 lift hydraulic roller camshaft helps to produce 425 hp making the ZZ383 a benchmark for all 383′s to be measured by. These crate engines are available in an orange finish (part #GMP-12498772-5R), a black finish (part #GMP-12498772-2R), and an anodized clear finish (part #GMP-12498772-4R).

The ZZ383 crate engines have the orange finish, black finish and anodized clear options.

Listed Price: $7,975.88 (orange), $7,998.88 (black), $7,998.88 (anodized clear)

Application: Street Rod, Street/Strip

Cost per hp: $18.77 (orange), $18.82 (black and anodized clear)

Specifications:

- Power: 425 hp at 5,400 rpm, 460 lbs/ft of torque at 4,500 rpm

- Displacement: 383 cid

- Bore x Stroke: 4.00-inch x 3.80-inch

- Compression Ratio: 9.6:1

- Block: Cast Iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: Steel hydraulic roller tappet

- Cam Lift: .509-inch Intake / .528-inch Exhaust

- Cam Duration at .050-inch: 222 degree Intake / 230 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: GM Fast Burn aluminum dual bolt pattern, 3/8-inch screw-in rocker studs

- Maximum GM Recommended rpm: 6,000

SBC Complete EFI Crate Engines

Budget Range SBC350 EFI Crate Engine

![]()

The SBC 350 with Holley’s Avenger TBI system (part #GMP-12530283-HFI) has dependability and torque to spare.

Pace’s 350 cid (GMP-12530283-HFI) may say “Heavy Duty Truck Engine” but in reality, it’s a durable daily driver topped with Holley Avenger EFI for extra dependability and torque to spare. This engine and EFI combination is an excellent choice for around town cruising with maximum horsepower and torque coming in at below 5,000 rpm. Based on GM’s 96-00 HD 1Ton truck replacement engine, Pace Performance topps it off with an Edelbrock rpm Air-Gap Intake and Holley’s self-tuning Avenger TBI fuel injection system. To give this engine a stealthy sleeper look they put on a set of OE black stamped steel valve covers and a dual snorkel air cleaner.

Listed Price: $5,488.88

Application: Daily driver

Cost per hp: $17.43

Specifications:

- Power: 315 hp at 4,600 rpm, 385 lbs/ft of torque at 4,000 rpm

- Displacement: 350 cid, 5.7L

- Bore x Stroke: 4.00-inch x 3.48-inch

- Compression Ratio: 9.4:1

- Block: Cast iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: Hydraulic roller

- Cam Lift: .414-inch Intake / .428-inch Exhaust

- Cam Duration at .050-inch: 191 degree Intake / 196 degree Exhaust

- Lobe Separation: 111 degree

- Cylinder Heads: Vortec cast iron, 3/8-inch pressed-in rocker studs

- Maximum GM Recommended rpm: 5,500

Mid-Range SBC with EFI

![]()

SBC 350 cid 350 hp crate engine with MSD EFI (part #GMP-19210007-MFI) sports the MSD Atomic EFI system and comes pre-programmed from Pace Performance.

Pace SBC 350 cid 350 hp crate engine with MSD EFI (part #GMP-19210007-MFI) is a great performing fuel injected small-block Chevy. Pace Performance starts with the Chevrolet Performance 350HO four-bolt block, with a high-lift camshaft that gives the engine its own unique, aggressive idle. The cam is based on the same one found in 1965-67 Corvette 327 engines, but it has even more lift and duration. This EFI crate is topped off with Edelbrock’s 7116 Performer rpm Vortec Intake and MSD’s new Atomic EFI master system. The engines are individually run for approximately 30 minutes or more on the dyno with various loads applied to insure proper engine break-in. The engine is then allowed to cool for final inspection. Pace pre-programs the MSD Atomic ECU and runs the engine through the self learn cycle prior to performance dyno pulls and final tuning.

Listed Price: $6,148.88

Application: Daily Driver, Street Rod, Street/Strip

Cost per hp: $17.57

Specifications:

- Power: 350 hp at 5,300 rpm, 407 lbs/ft of torque at 4,100 rpm

- Displacement: 350 cid, 5.7L

- Bore x Stroke: 4.00-inch x 3.48-inch

- Compression Ratio: 9.1:1

- Block: Cast Iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: Hydraulic flat tappet

- Cam Lift: .435-inch Intake / .460-inch Exhaust

- Cam Duration at .050-inch: 212 degree Intake / 222 degree Exhaust

- Lobe Separation: 112.5 degree

- Cylinder Heads: Vortec cast iron, 3/8-inch pressed-in rocker studs

- Maximum GM Recommended rpm: 5,500

Upper-Range EFI SBC Crate Engine

![]()

Pace’s ZZ430 (part #GMP-12496430-2) features a “HOT” camshaft with broad and responsive engine curves.

Rounding out the SBC 350 half of our crate engine review is the top runner in the EFI crate engine class. Pace’s ZZ430 (part #GMP-12496430-2) is based on Chevrolet Performance Parts limited edition ZZ430 crate engine originally produced in 1999. Using the time proven ZZ4 short block assembly adding GM’s HOT Cam, which was developed by GM Motorsports for LT1 and LT4 engines used in showroom stock road racing. The HOT Cam specs were developed to insure long term valve train durability along with a broad and responsive torque curve. This cam is specifically designed for use with 1.6 to 1 ratio roller rockers. The EFI system is the proven FAST EZ EFI self tuning system. Capping the 430 hp long block are GM Performance Fast Burn cylinder heads with all the components matched for use with the HOT Cam.

Listed Price: $7,348.88

Application: Hot Rod, Street/Strip, Daily Driver

Cost per hp: $17.09

Specifications:

- Power: 430 hp at 6,000 rpm, 430 lbs/ft of torque at 4,200 rpm

- Displacement: 350 cid, 5.7L

- Bore x Stroke: 4.00-inch x 3.48-inch

- Compression Ratio: 9.6:1

- Block: Cast Iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: steel hydraulic roller tappet

- Cam Lift: .525-inch Intake / .525-inch Exhaust

- Cam Duration at .050-inch: 218 degree Intake / 228 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: Aluminum, 3/8-inch screw-in rocker studs

- Combustion Chamber: 62cc

- Maximum GM Recommended rpm: 5,800

LS Complete Carbureted Engines

Budget Range LS Carbureted Crate Engine

![]()

The 5.3 LS – 327cid (part #GMP-19165628-K) is not only economical but a powerful entry level LS crate engine.

The 5.3 LS – 327cid power plant (part #GMP-19165628-K), sporting the same cubic inch displacement as the high-revving small blocks from the early 1960′s, is the top budget buy in the LS Carbureted Crate engines from Pace Performance. Introduced in 1962, the 327 was found in everything from fuel-injected Corvettes to the very first Camaro’s and was renowned for its high-rpm performance and surprising torque from a comparatively small-displacement V-8.

Listed Price: $5,579.88

Application: Daily Driver, Street Rod

Cost per hp: $15.94

Specifications:

- Power: 350 hp at 5,600 rpm, 370 lbs/ft of torque at 4,100 rpm

- Displacement: 327 cid, 5.3L

- Bore x Stroke: 3.78-inch x 3.62-inch

- Compression Ratio: 9.5:1

- Block: Cast Iron, with 6-bolt, cross-bolted iron caps

- Camshaft: Hydraulic roller tappet

- Cam Lift: .467-inch Intake / .479-inch Exhaust

- Cam Duration at .050-inch: 196 degree Intake / 201 degree Exhaust

- Lobe Separation: 116 degree

- Cylinder Heads: Aluminum cathedral port

- Maximum GM Recommended rpm: 6,000

Mid-Range Carbureted LS Crate Engine

![]()

Pace’s LS3 550 hp series of crate engines begin with the “as-cast” valve cover version.

Pace’s LS3 550 hp series of crate engines are a solid buy for street rodders. Starting with the Chevrolet Performance LS525hp crate engine and adding their 88958679 front distributor drive timing cover kit to create a custom look for this turnkey LS swap engine. No engine control module (ECU) or wiring harness is needed. Standard Chevy location radiator hose inlet and outlet. Front timing cover designed with heater hose ports. Available with “as-cast” valve covers (part #GMP-19259233-C) with chrome valve covers (part # GMP-19259233-C1), black valve covers (GMP-19259233-C2), polished valve covers (part #GMP-19259233-C3) or with orange valve covers (GMP-19259233-C5).

Pace's LS3 550 hp series of crate engines in chrome, black, polished and orange finishes.

Listed Price: $11,238.88

Application: Street Rod

Cost per hp: $20.43

Specifications:

- Power: 525 hp at 6,300 rpm, 489 lbs/ft of torque at 4,400 rpm

- Displacement: 376 cid, 6.2L

- Bore x Stroke: 4.060-inch x 3.620-inch

- Compression Ratio: 10.7:1

- Block: Cast Aluminum with 6-bolt cross bolted main caps

- Camshaft: Steel hydraulic roller tappet

- Cam Lift: .525-inch Intake / .525-inch Exhaust

- Cam Duration at .050-inch: 226 degree Intake / 236 degree Exhaust

- Lobe Separation: 110 degree

- Cylinder Heads: Aluminum L92 style ports

- Reluctor: 58X

- Maximum GM Recommended rpm: 6,600

Upper-Range Carbureted LS Crate Engine

![]()

Chevrolet Performance Parts LSX 454, the biggest and baddest crate engine in Pace’s Inventory.

It’s big, it’s orange and it’s BAD. 454 cid Chevy engines are always going to be associated with muscle cars and that tradition continues with the LSX454. Pace took the LSX bowtie block, stuffed it with an all-forged, super tough rotating assembly, and bolted on a pair of new GM deep breathing LSX six-bolt cylinder heads. The LSX six bolt cylinder heads are based on the race-derived LS7 heads that help deliver more than 500 horsepower in the Corvette Z06. They enable tremendous low end torque and great high rpm power. The Pace LSX 454 is delivered fully assembled with engine controller and harness. It also comes dressed with great looking, all new orange powder-coated valve covers with “LSX 454″ logos engraved and painted in black so you can’t be a sleeper with this mill.

Listed Price: $13,268.88

Application: Hot Rod, Street Rod, Street/Strip

Cost per hp: $21.06

Specifications:

- Power: 630 hp at 6,000 rpm, 605 lbs/ft of torque at 4,900 rpm

- Displacement: 454 cid, 7.4L

- Bore x Stroke: 4.185-inch x 4.125-inch

- Compression Ratio: 11:1

- Block: LSX Cast iron with 6-bolt cross bolted main caps

- Camshaft: Steel hydraulic roller tappet

- Cam Lift: .635-inch Intake / .635-inch Exhaust

- Cam Duration: .050-inch: 236 degree Intake / 246 degree Exhaust

- Lobe Separation: 110 degree

- Cylinder Heads: Aluminum LSX LS7 Rectangular style ports

- Reluctor: 58X

- Maximum GM Recommended rpm: 6,500

LS Complete EFI Crate Engine

All three of the LS crate engines with EFI are based on the LS3 long block from Chevrolet Performance Parts. All three are also set up by Pace Performance for the Tremec T-56 6-speed manual transmission. What makes these crate engines different from the factory crate engines in the past is the new “Connect-and-Cruise” crate powertrain systems. They’re factory-engineered engine combination that include all the electronic control modules, wiring harnesses and other key components you need with the simplicity of one part number. The specially calibrated controllers are designed for retrofit installation in older vehicles, for easier and quicker installation and operation.

Budget Level LS Crate Engine with EFI

![]()

Pace’s LS3 430 hp crate engine is based on the Chevrolet Performance Parts LS3.

The Chevrolet Performance LS3 430 hp crate engine (part #GMP-LS430T56) has broken new ground for efficiency and performance from a pushrod platform engine. The LS3 continues the engineering breakthroughs with revised cylinder heads featuring rectangle ports borrowed from the vaunted LS7. The heads feature 63 cc combustion chambers, 2.16-inch Intake valves, and 1.59-inch Exhaust valves. The camshaft features an aggressive .551-inches of lift on the Intake side with less overlap than the LS2 for even greater airflow and power.

Listed Price: $8,798.88

Application: Daily Driver, Street Rod

Cost per hp: $20.46

Specifications:

- Power: 430 hp at 5,900 rpm, 424 lbs/ft of torque at 4,600 rpm

- Displacement: 376 cid, 6.2L

- Bore x Stroke: 4.060-inch x 3.620-inch

- Compression Ratio: 10.7:1

- Block: Cast aluminum with 6-bolt cross bolted main caps

- Camshaft: Steel Hydraulic roller tappet

- Cam Lift: .551” Intake / .522” Exhaust

- Cam Duration at .050-inch: 204 degree Intake / 211 degree Exhaust

- Cylinder Heads: Aluminum L92 style ports

- Reluctor: 58X

- Maximum GM Recommended rpm: 6,600

Mid range LS Crate Engine with EFI

![]()

Pace Performance’s LS3 480HP crate engine (part #GMP-LS480T56).

Chevrolet Performance LS3 480 hp (Part #GMP-LS480T56) is the hot new small-block V-8 in the Pace lineup. It offers a high-revving 376-inch combination that represents generations of small block V8 development and engineering. Not only is the LS3 an amazing engine in its stock configuration, but with those high-flowing rectangular port cylinder heads, the LS3 is loaded with potential. To tap into this potential, the engineers at Chevrolet Performance Parts offer you the LS 376/480 – an LS3 with an upgraded camshaft that ups power by a whopping 50 horsepower.

Listed price: $9,218.88

Application: Daily Driver, Street Rod, Street Strip

Cost per hp: $19.21

Specifications:

- Power: 480 at 5,750 rpm, 475 lbs/ft of torque at 4,500 rpm

- Displacement: 376 cid, 6.2L

- Bore x Stroke: 4.060-inch x 3.620-inch

- Compression Ratio: 10.7:1

- Block: Cast aluminum with 6-bolt cross bolted main caps

- Camshaft: Steel hydraulic roller tappet

- Cam Lift: .525-inch Intake / .525-inch Exhaust

- Cam Duration at .050-inch: 219 degree Intake / 228 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: Aluminum L92 style ports

- Reluctor: 58X

- Maximum GM Recommended rpm: 6,600

King-of-the-Road Level LS Crate Engine with EFI

![]()

The LS3 525HP (part #GMP-LS525T56) features the ASA racing camshaft.

The Chevrolet Performance LS3 525 hp (part #GMP-LS525T56) blends the racing-derived ASA camshaft with the LS3 6.2L production engine to create the most powerful production-based crate engine in Chevrolet Performance’s portfolio. Delivering 525 horsepower at 6,300 rpm and 489 lb.-ft. at 4,400 rpm, this is the top of the line for factory GM crate engines. As delivered, the LS376/525 includes the Intake manifold, with the injectors, fuel rail and throttle body already installed, along with the water pump and ignition system. Front-end accessories must be obtained separately, along with the engine controller kit.

Listed price: $10,278.88

Application: Street Rod, Street/Strip

Cost per hp: $19.58

Specifications:

- Power: 525 hp at 6,300 rpm, 489 lbs/ft of torque at 4,400 rpm

- Displacement: 376 cid, 6.2L

- Bore x Stroke: 4.060-inch x 3.620-inch

- Compression Ratio: 10.7:1

- Block: Cast aluminum with 6-bolt cross bolted main caps

- Camshaft: Steel hydraulic roller tappet

- Cam Lift: .525-inch Intake / .525-inch Exhaust

- Cam Duration at .050-inch: 226 degree Intake / 236 degree Exhaust

- Lobe Separation: 110 degree

- Cylinder Heads: Aluminum L92 style ports

- Reluctor: 58X

- Maximum GM Recommended rpm: 6,600

The Cool Factor

![]()

Retro-Style Corvette Package (part #GMP-12499529-C) is filled with retro style components including the valve covers that are reproduction finned aluminum with the Corvette script.

The ultimate in cool factor for hot rods and street rods is Pace Performance’s GM 350/290 hp Crate Engine with Retro-Style Corvette Package (part #GMP-12499529-C). This retro crate SBC 350 delivers 290 hp at 5,100 rpm and a solid 326 lb/ft of torque at 3,750 rpm. This crate package includes many of the same parts and features as their other 290 hp packages but Pace Performance has changed out the Intake with a retro looking Edelbrock Performer EPS that is also drilled and baffled for a rear PCV valve. The valve covers are a reproduction finned aluminum with the Corvette script. To keep the retro look going, Pace Performance eliminated the HEI distributor and put in a small cap unit and an external remote mount coil.

Listed price: $3,728.88

Application: Hot Rod, Street Rod

Cost per hp: $14.34

Specifications:

- Power: 290 hp at 5,250 rpm, 332 lbs/ft of torque at 3,750 rpm

- Displacement: 350 cid, 5.7L

- Bore x Stroke: 4.00-inch x 3.48-inch

- Compression Ratio: 8.5:1

- Block: Cast iron, 2 piece rear seal, 4-bolt main caps

- Camshaft: Hydraulic flat tappet

- Cam Lift: .450-inch Intake / .460-inch Exhaust

- Cam Duration at .050-inch: 222 degree Intake / 222 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: Cast Iron, 3/8-inch pressed in rocker studs

- Maximum GM Recommended rpm: 5,100

ZZ4 with Holley Tri-Power Turnkey Crate Engine (Part #GMP-24502609-6B)

![]()

Pace Performance took their best selling ZZ4 crate engine and added a custom Tri-Power Intake with 3 specially tuned Holley carbs. Major cool factor and bonus points in this crate engine.

This crate engine looks bad, sounds badder, and has a price tag comfortable enough for every hot rodder or muscle car aficionado. Pace Performance took the Chevrolet Performance’s best selling ZZ4 crate engine and added a custom Tri-Power Intake with 3 specially tuned Holley carbs and sent it to the dyno shop. This set-up just flat outperforms.

Listed Price: $7,428.88

Application: Hot Rod, Street Rod, Street/Strip

Cost per hp: $20.98

Specifications:

- Power: 354 hp at 5,300 rpm, 415 lbs/ft of torque at 3,900 rpm

- Displacement: 350 cid, 5.7L

- Bore x Stroke: 4.00-inch x 3.48-inch

- Compression Ratio: 10:1

- Block: Cast Iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: Steel hydraulic roller tappet

- Cam Lift: .474-inch Intake / .510-inch Exhaust

- Cam Duration at .050-inch: 208 degree Intake / 221 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: Aluminum, 3/8-inch screw-in rocker studs

- Combustion Chamber: 58cc

- Maximum GM Recommended rpm: 5,800

The Chevrolet Performance ZZ383/430 hp Engine with 8-Stack EFI (part #GMP-12498772-8STK)

![]()

The ultimate in coolness has to be the 8-stack Chevrolet Performance ZZ383 with a FAST EZ-EFI ECU and harness. This crate engine will make any street rod look custom with throw-back styling.

The ultimate hot rod/street rod engine for both looks and performance. Pace Performance shows off with a crate engine that has great looks and an EFI system that outperforms a carburetor. They took the new 8-Stack fuel injection system, mounted it on a brand new Chevrolet Performance ZZ383 and then added a FAST EZ-EFI ECU and harness. The Dyno results were surprising with 430 hp at5200 rpm. More surprising was the tight air fuel ratio reading which stayed between 13.3 and 13.6 throughout multiple pulls on the dyno. During pull number 2 the FAST system started learning and making self adjustments which further enhanced the engine’s performance.

Listed price: $11,618.88

Application: Hot rod, Street Rod, Street/Strip

Cost per hp: $27.02

Specifications:

- Power: 430 hp at 5,200 rpm, 475 lbs/ft of torque at 4,300 rpm

- Displacement: 383 cid

- Bore x Stroke: 4.00-inch x 3.80-inch

- Compression Ratio: 9.6:1

- Block: Cast iron, 1 piece rear seal, 4-bolt main caps

- Camshaft: Steel hydraulic roller tappet

- Cam Lift: .509-inch Intake / .528-inch Exhaust

- Cam Duration at .050-inch: 222 degree Intake / 230 degree Exhaust

- Lobe Separation: 112 degree

- Cylinder Heads: GM Fast Burn aluminum dual bolt pattern, 3/8-inch screw-in rocker studs

- Maximum GM Recommended rpm: 6,000

Conclusion

No matter what type of hot rod, street rod or daily driver you have, Pace Performance has a very affordable crate engine solution for motoring down the road, throwing some traction at an autocross or just showing off at a car show. We’ve added the horsepower per dollar value to each of the crate engines listed above as a reference only. There is no way to accurately put a dollar amount on a crate engine that has an 8-stack EFI system. That is just pure “wow” factor hard at work.

From the most basic crate engine to the over the top 8-stack EFI crate, each of these kits represent a great value for the dollar. Add the warranty to the mix and you have a reliable performer with an unbeatable price tag.

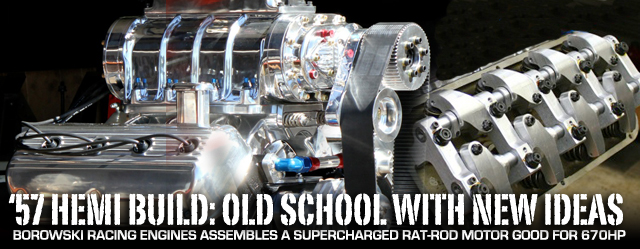

Other types of superchargers may be more efficient and fit comfortably under the hoods of most cars. But if you don’t mind cutting a little sheet metal to clear a fat blower case, and you don’t mind bending your neck occasionally to see around that obtrusive air scoop–then a “Jimmie” blower is for you.

Other types of superchargers may be more efficient and fit comfortably under the hoods of most cars. But if you don’t mind cutting a little sheet metal to clear a fat blower case, and you don’t mind bending your neck occasionally to see around that obtrusive air scoop–then a “Jimmie” blower is for you.